Production Control~ The average delivery delay per year: Achieved zero defects by strict control procedure ~

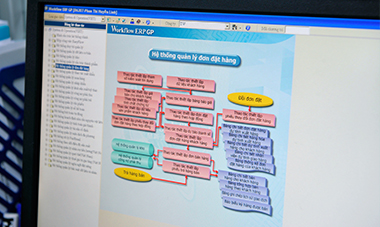

Controlling production progress by ERP system and computers

* Adopting ERP system to manage automatically orders, quantity, shipping date by computers.

- Prompty finding and handling late delivery problems arising out through each process.

- Preventing product defects arising from manual operations and miscommunication.

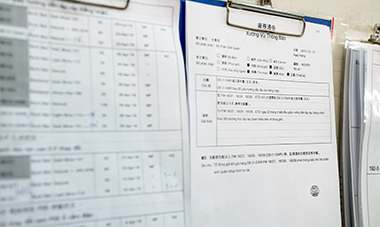

Enhancing the acceptance and understanding among employees about notification matters

Any changes on specifications, quantities, other change requests shall be shown on the signboard as specified by each departments to notify everybody.

- All employees can understand clearly when the new requirements were given to them to avoid miscommunication.

The semi-automation due to the introduction of roller conveyor system and the development of our original machines.

* Helping facilitate the smooth transportation by using the roller conveyor system instead of pallet jack.

- Preventing product damage as well as reducing the time loss.

* Through joint development with equipment manufacturers to introduce the genuine equipment for multi-stage operation simultaneously.

- Reducing of mass production cost as well as improvement of the product accuracy.

Safety measures for employees using of machines.

* Representing all operation methods, using precautions on the board and visualizing such notifications for all machines.

- All employees can operate the equipment after clearly understanding the method.

* Furthermore, the content of operations, starting time – ending time, check points are also shown and visualized on the board for each machines.

- Employees can operate explicitly and consistently.

General Production Meetings every morning and Individual Department Meetings held once a week

* General Production Meetings every morning

- The departments prompty raise, review and resolve the problems arising every day.

* Individual Department Meetings held once a week

- Implementing the investigation of the causes, consideration of improvement of problems incurred in previous week.

Quality Control~ Annual Defect Rate: Thoroughly managing to minimize the defect rate of production to the low rate of 0.28% ~

Plain wood processing by using CNC machine

* Introducing 15 CNC machines for the processing stage.

(As of April, 2022)

- Reducing operations of processes, stabilizing and improve production efficiency and quality.

Primary inspection at each work-in-process

* It is required to do primary inspection before mass production for each work-in-process

Each group leader, team leader of each department shall check each checkpoint which is recorded in the workplace of each work‐in‐process against the production drawings, and they are checked twice by group leader -> team Leader .

- Avoiding the product defects found after mass production completed.

Full inspection using Jig tool and random check

* Inspecting 100% of the products by using the Jig tool to check key positions on the product.

- Preventing structural defects such as defects which are impossible-to- assembly.

* Conduct the random inspection of products twice before and after the processing of plain wood on other materials.

- Preventing defects after finishing.

Using LED lights to inspect the appearance of total products after finishing.

* Inspecting 100% of product’s appearance twice after the products finished the basecoat and top coat.

- By using LED lights to ensure required brightness (Over 500 LUX), we check errors such as scratches, cracks, sinkholes, on the product’s surface.

Holding Monthly General Quality Meeting

* Establishing the data on descriptions of product defects monthly and distributing them to each department.

Base on this, holding General Quality Meeting to investigate the cause of defects, review the improvement plans and check the implementation after the improvement.

- Resolving item by item to prevent similar defects from arising, and aim to further reduction of defect rates.

R&D and Sales~ Market Research through multinational groups and Proposal for Original products ~

Customer Services by native language.

* Every sales staff can communicate with customers in English, Chinese and Japanese.

During job performance such as negotiation, making quotation, phone call, sending mail, we will handle the communication by your native language.

- You do not need to pay any effort for matters such as interpretation, translation, and therefore, our communication becomes smoothly.

Development of original products and offering ideas

* We not only support OEM production orders from customer but also proactively develop and design ideals to produce our own products based on the results of market research.

- Our company was established with the members from countries like Malaysia, Taiwan, China, Japan, hence, our market research is performed with various viewpoints to create new design ideas.

Offering drawings, 3D images with AUTOCAD system of Research and Development Department.

* By using AUTOCAD system, we can make a price quotation of the products that customers required and provide drawings, 3D images.

- We make drawings for even simple designs or pictures and provide proposals for the products.

Showroom displayed with many original products

* Our company showroom specializes in displaying original products developed by ourselves based on the result of market research.

- Through these products, we listen to the aspirations of customers, conduct coordination to launch new products with originality and meet customer satisfaction.

* Simultaneously, we also prepare a comfortable space for customers to be able to talk freely.

Meeting and discussing in other countries

* Not only greeting customer’s visit at our office, our company will go abroad twice per year to visit customer office and work at customers’ companies.

- Not only from the local Vietnam company side, we always try to build close relationships and quickly respond system to the needs of customers through our visit to your company to submit proposal for new product development, review and resolve the problems arising.